When it comes to industrial hoses, there are a variety of factors to consider when making a purchase. From durability and flexibility to cost and safety, the decision must be handled with an eye for detail.

But how do you know which hose is right for your needs? Navigating the world of industrial hoses can be complicated, so here are some key things to think about before buying one.

Specifically, we’ll look at material composition, connection type compatibility, size requirements, and pressure expectations.

By considering these ahead of time, you’ll make sure that you’re selecting the best solution available on the market today.

Understanding Industrial Hose Types

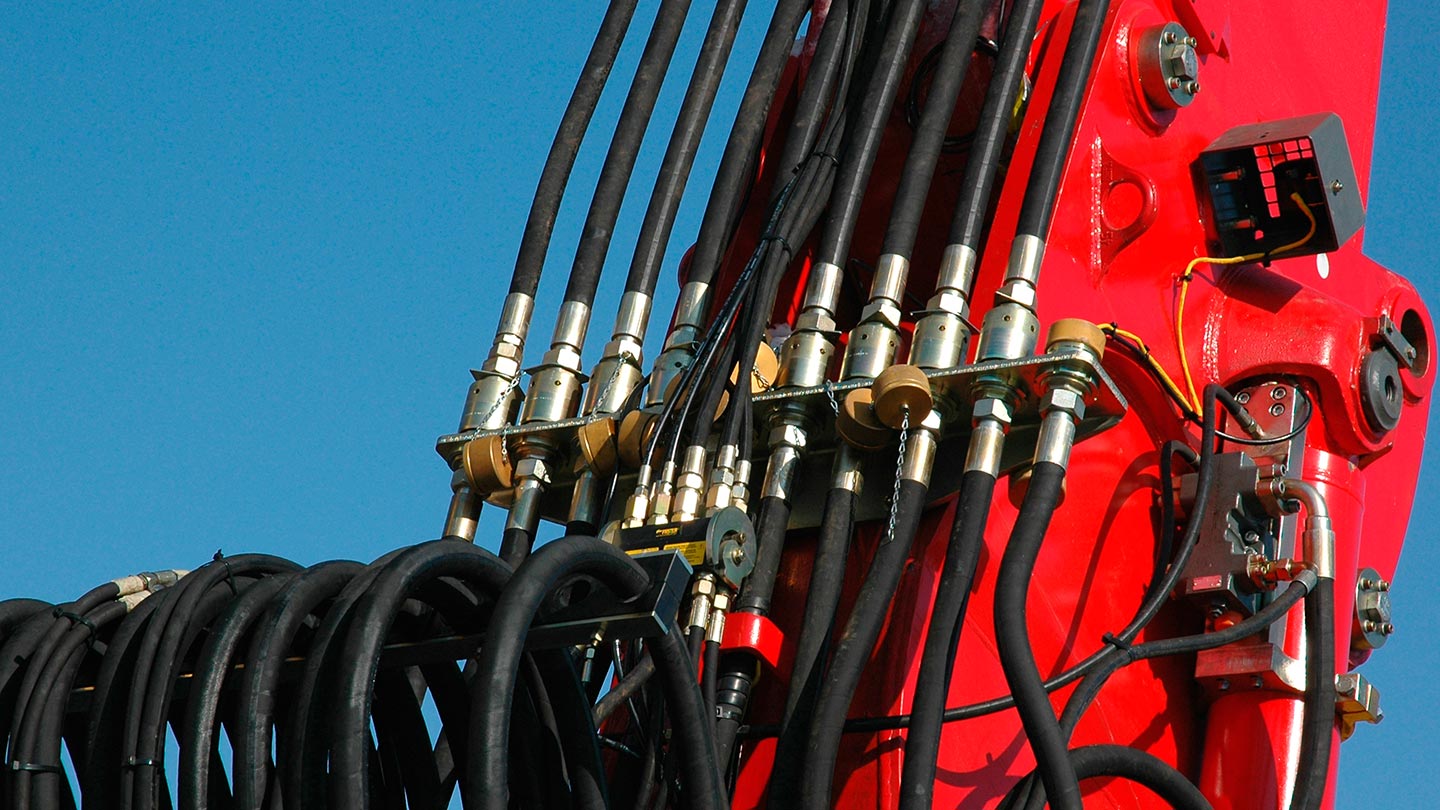

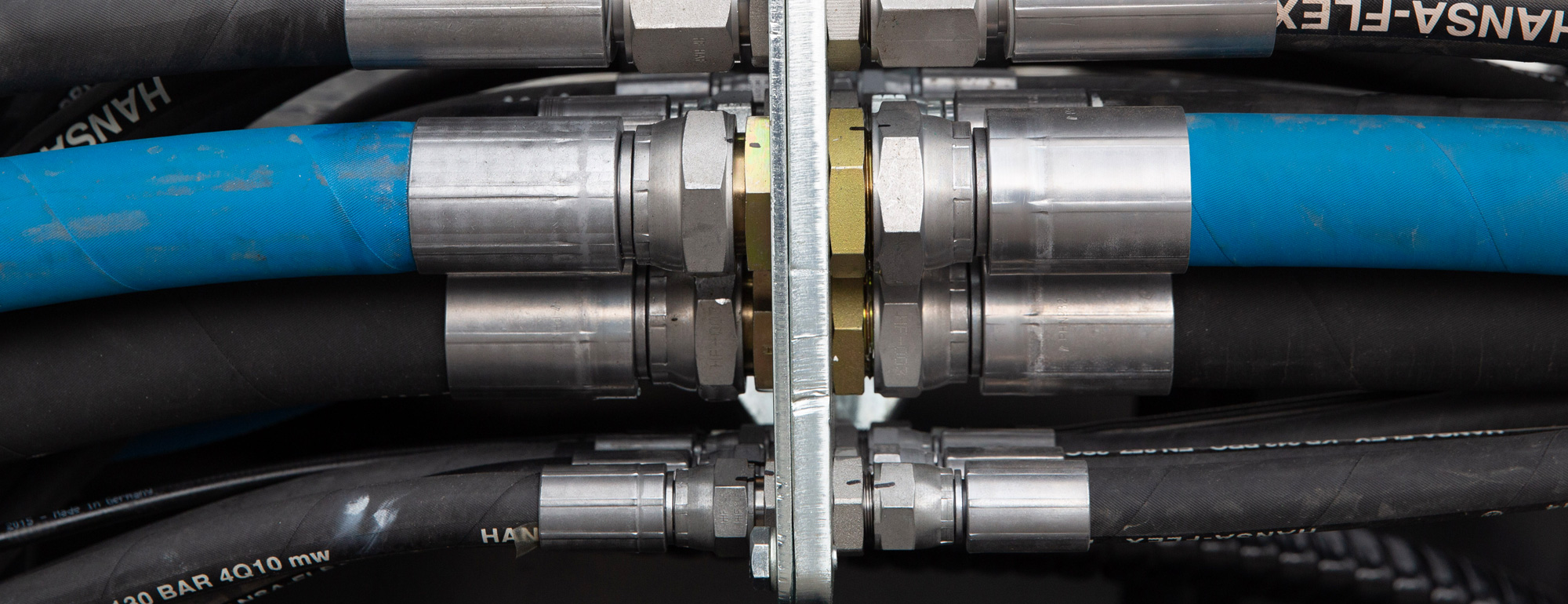

Industrial hoses come in a variety of shapes and sizes to meet the needs of different applications. From smaller diameter tubing for air and water transfer to larger reinforced hoses designed for more demanding tasks such as chemical or petroleum transportation, it’s important to select the right hose material for each application.

Rigid metal tubes provide excellent protection against abrasion damage while remaining flexible enough to handle sudden movement from machinery; however, they tend to be more expensive than rubber-reinforced options which offer good flexibility at lower cost.

Polyurethane-lined steel wire reinforced hoses are often used when dealing with hazardous materials since their construction provides superior protection against heat and chemical damage compared to traditional PVC-coated models without sacrificing flexibility or strength.

Finally, stainless steel braided hydraulic hoses feature multiple layers of woven steel wrapped around a core made out of tough yet pliable plastic providing outstanding corrosion resistance along with superior strength that can withstand extreme temperatures — making them the ideal choice in marine environments where saltwater could quickly corrode unprotected equipment leading premature failure and costly repairs down the line.

Ultimately, understanding what type of industrial hose best suits your application is key when making sure that you get the maximum performance out of your system without compromising safety or reliability – no matter how challenging its environment may be!

Choosing a Durable Material for Your Industrial Hoses

When choosing a durable material for industrial hoses, it is important to consider not only the long-term use and performance of the hose but also factors such as temperature range, pressure rating, chemical compatibility, and abrasion resistance.

PVC offers an economical and lightweight option that is great for general-purpose applications like air or water transfer due to its good flexibility and weather resistance.

For more demanding uses with higher temperatures or pressures, thermoplastic elastomers (TPE) provide better heat tolerance than PVC while remaining flexible enough for most uses. Highly abrasive materials may require reinforced rubber hoses made from natural rubber compounds or synthetic rubbers such as nitrile butadiene rubber (NBR).

Natural rubber hoses offer superior oil/fuel compatibility compared to synthetics while providing excellent flexibility even at very low temperatures.

Silicone provides outstanding durability at extremely high temperatures up to 500°F (260 °C), making it ideal for steam services, hot oils, and other conditions where prolonged exposure above 400°F would cause degradation of most other materials over time.

On the opposite end of the spectrum are cryogenic liquids requiring special care when selecting suitable hose materials since many traditional options can become brittle at extremely cold temperatures below -65°F (-54 °C). In these cases, fluoropolymer-lined metal hoses provide reliable protection from corrosion without sacrificing flexibility or strength needed for safe operation.

All in all, there are numerous factors that must be considered when selecting a durable material so make sure you take some time researching your specific requirements before deciding on a solution that fits both your needs —and budget—while delivering optimal performance over its lifetime

Considering Special Features of Different Industrial Hoses

When it comes to industrial hoses, there are a variety of special features available that can make all the difference. From reinforced flexible hoses for extra strength and durability to anti-static hoses designed for use in explosive environments, the choice of the hose is dependent on the application.

Some industrial hoses come with temperature ratings so you know how much heat they can withstand before failing. Different materials such as nylon and PVC also have different properties which affect performance and lifespan — some are better suited to certain tasks than others.

It’s also important to consider whether your chosen hose will be exposed to chemicals or oils; this will determine what type of protective coating you need to ensure its longevity.

Some substances require specialist protection such as stainless steel braiding or polyurethane sheathing, while other applications may only require an additional layer of insulation or rubber coating.

Finally, when selecting an industrial hose for your application, make sure you check the pressure rating too – many specialized applications require higher pressure ratings than standard models can handle safely and effectively.

With so many factors involved it pays off in terms of cost savings over time if you take time at the outset to consider all these details carefully!

Conclusion

When it comes to purchasing industrial hoses, there are many factors to consider. From material and size to temperature range and pressure ratings, the right industrial hose for your application can make a big difference in performance and safety.

Rent One Hose is an experienced industrial hose manufacturer that provides an extensive selection of products designed for various industries such as construction sites, mining operations, warehouses, agricultural facilities, and more.

With years of experience in providing quality hoses at competitive prices, Rent One Hose offers customers a reliable solution when selecting the perfect hose for their needs – no matter what those needs may be.