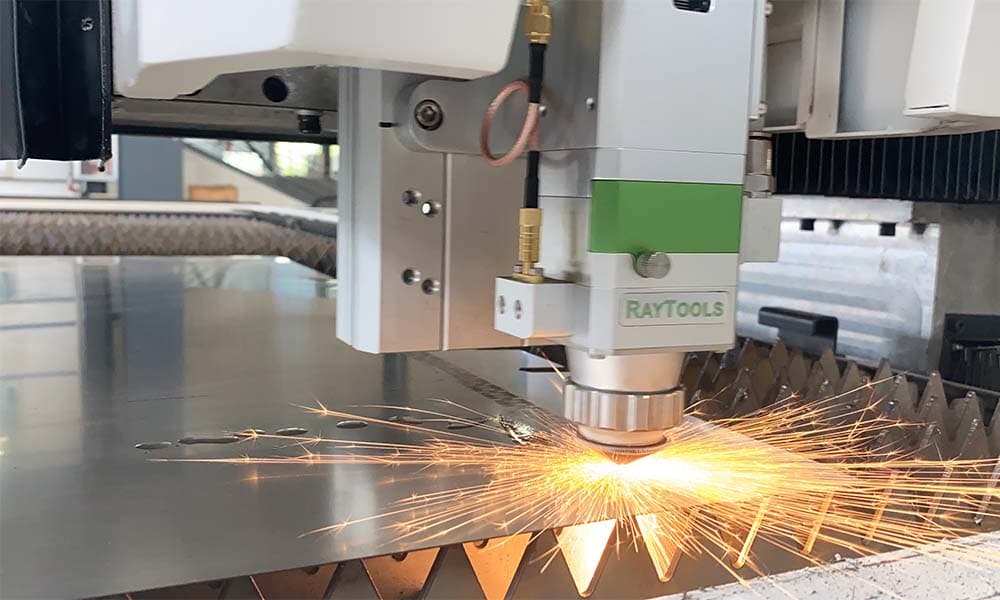

Safety in the workplace is a top priority for any employer or business. Laser-cutting operations have the potential to cause serious injuries if not handled properly, making it even more important that appropriate safety protocols are followed at all times.

This article provides an overview of safety guidelines related specifically to laser cutting operations, helping employers ensure their workers remain safe on the job.

From understanding the risks and utilizing proper personnel protection equipment (PPE) to following specific operating procedures and maintaining up-to-date certifications, this article outlines key steps businesses can take to guarantee safety while using lasers in their cutting processes.

Laser Cutting Safety Equipment and Procedures

When it comes to laser-cutting operations, safety is of paramount importance. To ensure a safe and hazard-free environment for employees, employers must put in place the appropriate procedures and equipment.

At all times, operators should wear protective gear such as face shields, helmets, and gloves when working with lasers. Training courses should be provided to explain the correct use of these items as well as outline any potential hazards associated with their use.

Its also important that work surfaces are kept free from obstructions or debris which could cause an accident during operation. The area where laser cutting takes place must also be properly ventilated to reduce the risk of hazardous fumes being inhaled by workers or bystanders.

Furthermore, fire extinguishers should be placed nearby in case sparks from the laser contact something combustible like sawdust or plastic shavings created during operation.

Finally, regular inspections of both tools and equipment should be carried out to make sure they remain in good condition for safe use at all times while operating lasers; this includes checking cables for frayed areas or other signs of damage which may lead to electrocution if left unchecked!

Regular Maintenance of Laser Cutting Equipment

Regular maintenance of laser-cutting equipment is essential for ensuring safety in the workplace. To ensure that laser-cutting machines remain safe and effective, operators should check the power output levels of their machines regularly.

Careful inspection should also be taken to make sure all guards and shields are securely fastened and functioning properly. It’s important to keep the lens clean by wiping it with a clean cloth or using an approved cleaning solution after each use; this will help prevent any potential damage caused by excessive build-up of debris from cut materials.

Additionally, checking that no parts have been damaged or worn due to extended use is highly recommended, as worn-out parts may lead to more serious problems such as fires or explosions. Finally, regular servicing of your machine can help detect any issues early on before they become major issues requiring costly repairs or replacements.

By making sure your laser cutting equipment is well maintained, you’ll be able to enjoy its benefits while keeping yourself and other workers in your facility safe from harm.

Risk Assessments and Hazard Identification

Risk assessments and hazard identification are essential components of any laser-cutting operation. Companies should create a comprehensive system to identify, assess, and manage potential risks associated with the use of lasers.

This includes analyzing the safety protocols already in place as well as developing new ones that can be used when necessary. Additionally, employers need to keep up-to-date on relevant regulations regarding laser cutting operations and ensure their company is compliant at all times.

Furthermore, companies must perform regular inspections to identify hazardous conditions or practices before they lead to an accident or injury. Finally, employees who operate laser cutters need to be adequately trained in proper safety procedures so they can recognize potential hazards and take appropriate corrective action if needed.

By taking these steps, businesses can reduce the risk of accidents or injuries due to improper handling of lasers while still achieving maximum efficiency from their machines.

Conclusion

The use of laser cutting machines is an efficient way to produce precise cuts and shapes, which are necessary for many manufacturing operations. However, it is important to remember that these powerful tools also come with certain safety hazards.

Following the guidelines provided by https://zltechlaser.com/sheet-fiber-laser-cutting-machine on ensuring safety in the workplace can help ensure that laser-cutting operations run smoothly and without incident. By following these guidelines, companies can be sure to keep their workers safe while still providing high-quality products at a competitive cost.